We are often unaware of the marvellous work that goes into the production of EVOO.

A meticulous process that is very important in order to obtain a quality product to satisfy the most demanding palates. A process that has numerous stages in order to achieve an optimum result with unique nuances.

Do you want to know our elaboration process? Enter into a unique experience for your palate:

1. Harvesting

One of the key steps in the production of Extra Virgin Olive Oil is harvesting. We must pay special attention to this stage, as the production process depends on it and the olives must arrive in good condition at the oil mill.

The olives must be harvested at the right moment of ripeness in order to obtain the best nuances and aromas of the EVOO. To carry out this process we can use different methods, such as vibration, which consists of shaking the tree mechanically so that the fruit falls; another option is the “vareo”, the most traditional method, hitting the branches of the tree with sticks about three metres long.

2. Transport

Once the olives have been harvested, they must be transported to the oil mill in order to obtain the highest quality end product.

Both harvesting and transport must be carried out with the utmost care so that the olives are not damaged.

3. The cleaning and washing process

Once the olives have arrived at the mill, they are separated from both the leaves and the branches by means of an air current. Once this first cleaning has been carried out, if the mill master considers that a brief washing is necessary, the remains of earth and stones are removed with water. For a correct treatment of the olives we have to take into account a correct rotation of the washing water.

4. The milling process

Next, we move on to milling, the process by which the olives are crushed in order to extract the EVOO.

These olives must be crushed as soon as possible in order to achieve maximum quality and prevent the fruit from deteriorating, only in this way will we obtain a quality EVOO.

What does this milling consist of? A paste with a specific granulometry is obtained, the result of the process of breaking and crushing the whole olive, including the stone, the aim being to free the small particles of oil that are inside the stone.

At this stage we must be very careful, as if the crushing is excessive, an emulsion (homogeneous paste) is usually formed, in which the subsequent separation of the oil is usually more complicated and complex.

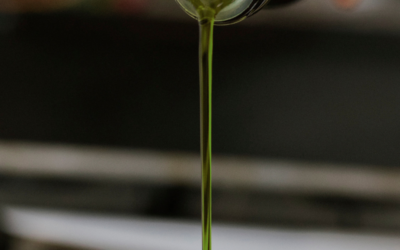

5. Oil extraction phase

The extraction phase is marked by centrifugation, the paste obtained from the milling process is introduced into a centrifuge in order to completely separate the oil, water and pomace. The centrifugal force pushes the heavier particles to the outside, which are extracted from different parts of the oil.

At this stage, the control of the process is focused on controlling the variable speed of the rotor, carried out by a servomechanism, and the separation between the discs.

6. Storage

At this stage of the process, the oil is stored or deposited in huge stainless steel tanks awaiting packaging. These tanks can hold a large capacity and protect the oil from light and air.

Here the process constantly monitors the temperature by means of an optical pyrometer, in which the level is electronically measured by an ultrasonic sensor and an inert oxidising gas atmosphere is maintained to ensure the quality and freshness of the processed products. The temperature must be between 15 and 18º. The conditions in which the oil remains in the cellar are important for the quality to remain intact.

In this way, with the same care and attention to detail that we put into the process, we offer you the know-how of our experience to extract the best quality from the olives and turn it into a first-class oil, a unique experience for your palate!